Vores automatiske maskiner til påfyldning og afdækning af stjernehjul er egnede til at udfylde vandtynde til mellemstykke produkter, såsom flydende medicin, toner, perm lotion, luftfriskere, hudpleje osv. De er udstyret med kompakt konfiguration, lille område besat, pænt udseende, let tilpasning og bred anvendelighed, hvilket gør dem kan bruges i vid udstrækning inden for farmaceutiske, pesticider, daglige kemikalier, fødevarer eller andre industrier.

I disse serier styres påfyldnings- og afdækningstiltagene af nøjagtig mekanisk transmission, hvilket kan garantere produktets kvalitet effektivt. Alle arbejdsstationer, inklusive påfyldning, cap-fodring, afdækning er udstyret omkring et stjernehjul, så både arbejdsområdet og de nødvendige operatører kan reduceres kraftigt. Den automatiske og uafbrudt produktionstilstand kan hjælpe med at garantere den produktionsvolumen, du har brug for. Vi vælger godt materiale og dele til montering af vores maskiner. Alle dele kommer i kontakt med produkterne er fremstillet af rustfrit stål af fødevarekvalitet, og alle de pneumatiske og elektriske dele er kendte mærkeprodukter fra Tyskland, Japan eller Taiwan. Det er innovationsdesignet og dele af god kvalitet, der sikrer, at disse serier af maskiner indtager den førende position absolut på hjemmemarkedet for flydende emballage.

Vores Rotary Star Wheel Filling and Capping Machine passer specielt til produktion af en enkelt slags produkter i store partier af produktion.

Produktionsstrøm:

Påfyldning --- Fodringsindsatser --- Tryk på indsatser --- Indføringshætter --- Afdækning

Design efter dine behov.

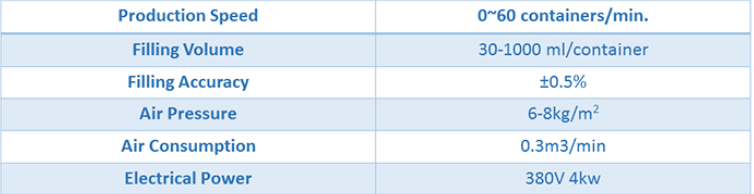

Vigtigste tekniske specifikationer

Hurtige detaljer

Type: Capping Machine, Fylde og caping machine

Tilstand: Ny

Anvendelse: Drik, kemisk, mad, maskiner og hardware, medicinsk, kosmetisk, medicin, kemisk osv.

Drevet type: Elektrisk og pneumatisk

Automatisk karakter: Automatisk

Spænding: 380V

Effekt: 4kw

Emballagetype: Flasker

Emballeringsmateriale: Glas, metal, plast

Oprindelsessted: Shanghai, Kina (fastlandet)

Mærkenavn: VKPAK

Dimension (L * B * H): 1670 * 1350 * 1675

Vægt: 600 kg

Certificering: ISO9001

Service leveret efter salg: Ingeniører til rådighed for serviceudstyr i udlandet

Kvalitetskontrolsystem: ISO9001: 2008

On-site Management System: 5S

An automatic cream filling and capping machine is a highly advanced packaging machine that is specifically designed to package creams and lotions into various types of containers such as jars, bottles. This machine is essential for businesses in the cosmetics industry who want to streamline their packaging process and increase their productivity.

One of the key benefits of an automatic cream filling and capping machine is its ability to fill and cap containers at a high speed. This is achieved through the use of advanced automation technology that allows for fast and accurate filling and capping. In addition, the machine is highly versatile and can handle a wide range of container sizes and shapes, making it ideal for businesses with diverse product lines.

The machine works by first filling the containers with the cream or lotion using a dosing pump that accurately dispenses the required amount of product. The containers are then capped using a capping head that tightly seals the product to ensure freshness and prevent spillage. The capping head can be customized to accommodate different types of caps such as screw caps, flip-top caps, and snap-on caps.

One of the key features of an automatic cream filling and capping machine is its ease of use. The machine is equipped with a user-friendly control panel that allows for easy adjustment of settings such as filling volume, capping torque, and speed. This makes it easy for operators to set up and operate the machine, reducing the risk of errors and improving overall efficiency.

Another important feature of an automatic cream filling and capping machine is its high level of hygiene. The machine is designed to be easy to clean and sanitize, with smooth surfaces and minimal crevices that can trap dirt and bacteria. This is particularly important in the cosmetics industry, where hygiene is essential for ensuring product quality and safety.

In conclusion, an automatic cream filling and capping machine is a valuable investment for businesses in the cosmetics industry. With its advanced automation technology, versatility, ease of use, and high level of hygiene, this machine can help businesses increase their productivity, improve their packaging quality, and stay ahead of the competition. When choosing a cream filling and capping machine, it is important to consider factors such as production capacity, container size and shape, and the type of cream or lotion being packaged.