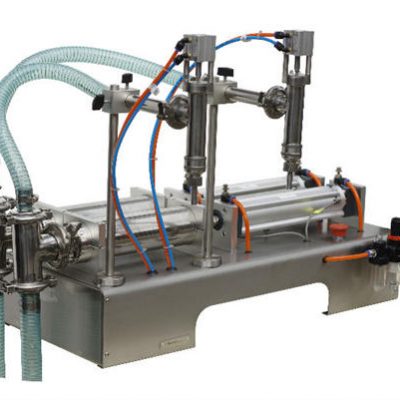

En påfyldningsmaskine til opvaskemiddel er en type automatiseret udstyr, der er designet til at fylde flasker eller beholdere med opvaskemiddel. Den bruger typisk en række pumper, sensorer og dyser til nøjagtigt at måle og dispensere den korrekte mængde opvaskemiddel i hver beholder. Disse maskiner kan bruges i industrielle eller kommercielle omgivelser for at øge produktionseffektiviteten og nøjagtigheden.

specifikationer

opvaskemaskine

1. Mød GMP med CE-certifikat

2. Materiale: 304 eller 316 rustfrit stål

3. Betal:T/T,L/C

Beskrivelse

EU's CE

ISO9001

Opfyld kravene fra GMP

lang levetid, lav vedligeholdelsesgrad

Hovedfunktion

Maskinen er avanceret påfyldningsmaskine med høj præcision, der automatisk kan gennemføre flasketælling, påfyldning og afdækningsproces.

Funktioner

1. Kompakt struktureret, flot, let at betjene og meget automatiseret.

2. Komponenternes kontakt med materiale er lavet af rustfrit stål, let at rengøre.

3. Påfyldningsvolumen styres med filmventiler for at sikre nøjagtighed.

4. Højhastigheds og meget nøjagtige påfyldningsventiler sikrer ingen lækage.

5. Det er udstyret med et højeffektivt fodringssystem.

Sprogvalg

Overvågningssprog: engelsk, spansk, arabisk, portugisisk, russisk, italiensk, fransk, koreansk.

Vigtigste egenskaber:

1. Lineær type stempelpåfyldningsmaskine specielt designet til klæbrig væske, såsom vaskemiddel, shampoo, lotion, smøreolie, spiseolie osv. international avanceret teknologi, allerede godkendt af velkendte virksomheder som Bayer. Høj påfyldningsnøjagtighed, enkel struktur, stabilt arbejde, bred anvendelse. Optælling af flaskeindløb, kvalitativ påfyldning, flaskeudløb sker automatisk.

2. Ikke kun hele 13 påfyldningsdysers dosering kan groft justeres, men også hver enkelt påfyldningsdyser kan finjusteres.

3. Kan huske mange parametre, nyttige til forskellige specifikationer ændret, al påfyldningsdosis kan justeres ved berøringsskærm.

4. Væskekontrol til normal fungerende væskeniveaukontrol, lyd- og lysalarmanordning, garanterer væskeniveauet i normal tilstand; kan også opnås til indløbsventil/pumpestyring.

5. Materiale udløbssamlinger alle vedtager hurtig montering type (klemmetype), let at rengøre. Tætningspakninger vedtager fluorgummi O-ring; sanitære forbindelsesrør.

6. Med beskyttelseskasse, dryprende, hovedmaterialer er lavet af SS304, fugtede dele er lavet af SS316L.

Vigtigste tekniske parameter

| Vare | Navn | Teknisk parameter |

| 01 | Maskindimension (L * W * H) | 2200mm * 1400mm * 2800mm |

| 02 | Maskinens vægt | Cirka 1400 kg |

| 03 | Beholderåbningens indre diameter | ≥φ35mm |

| 04 | Egnet beholder | 1Liter .2Liter |

| 05 | Beholderhøjde | 80-350mm |

| 06 | Strømforsyning | AC 380V; 50 HZ |

| 07 | Strøm | 5kW |

| 08 | Påfyldningsnøjagtighed | ≤ ± 1% |

| 09 | Luftkilde | 0,6Mpa stabil og ren trykluft |

| 11 | Antal påfyldningsdyser | 13 |

| 12 | Transportørhøjde | 900mm ± 50mm |

| 13 | kapacitet | ≤3200 flasker / time (tag vand som test) |

| 14 | Flaske i foderetning | Fra venstre mod højre |

Hurtige detaljer

Type: Påfyldningsmaskine

Tilstand: Ny

Anvendelse: Kemisk

Emballagetype: Flasker

Emballagemateriale: Træ

Automatisk karakter: Automatisk

Drevet Type: Pneumatisk

Spænding: 220v

Effekt: 3KW

Oprindelsessted: Shanghai. Kina (fastland)

Mærkenavn: VKPAK

Dimension (L * B * H): 2200mm * 1400mm * 2800mm

Vægt: 1400

Certificering: CE

Service leveret efter salg: Ingeniører til rådighed for serviceudstyr i udlandet

materiale: SS304

PLC: Panasonic

Berøringsskærm: Panasonic

Påfyldningsmaskiner til opvaskemiddel er specielt designet til at pakke opvaskemidler i forskellige typer beholdere. Disse maskiner er essentielle for virksomheder i rengøringsbranchen, der ønsker at strømline deres pakkeproces og øge deres produktivitet. Der findes flere typer påfyldningsmaskiner til opvaskemiddel på markedet, hver med sine unikke egenskaber og fordele.

En af de mest populære typer påfyldningsmaskiner til opvaskemiddel er det volumetriske fyldstof. Denne maskine fungerer efter forskydningsprincippet og bruger et stempel til at fylde beholderne med den nøjagtige mængde væske, der kræves. Denne type maskine er meget nøjagtig og er velegnet til emballering af væsker med konstant viskositet.

En anden type påfyldningsmaskine til opvaskemiddel er gravitationsfylderen. Denne maskine arbejder efter tyngdekraftsprincippet og bruger en tragt til at fylde beholderne med væsken. Væsken dispenseres derefter i beholderne baseret på væskens højde i tragten. Denne type maskine er ideel til emballering af væsker med lav viskositet og er meget omkostningseffektiv.

Den tredje type påfyldningsmaskine til opvaskemiddel er overløbsfylderen. Denne maskine arbejder efter overløbsprincippet og bruger en tragt til at fylde beholderne med væsken. Væsken dispenseres derefter i beholderne baseret på højden af væsken i tragten. Denne type maskine er ideel til emballering af væsker med høj viskositet og kan håndtere væsker med store partikler.

Når du vælger en påfyldningsmaskine til opvaskemiddel, er det vigtigt at overveje faktorer som størrelsen af din produktionslinje, væskens viskositet, typen af beholdere, du vil bruge, og produktionshastigheden, du har brug for. Det er også vigtigt at overveje den nemme vedligeholdelse og maskinens pålidelighed.

Afslutningsvis er en påfyldningsmaskine til opvaskemiddel en afgørende investering for virksomheder i rengøringsbranchen. Med den rigtige maskine kan virksomheder øge deres produktivitet, forbedre kvaliteten af deres emballage og spare tid og penge. Når du vælger en påfyldningsmaskine til opvaskemiddel, er det vigtigt at overveje faktorer som størrelsen af din produktionslinje, væskens viskositet, typen af beholdere, du vil bruge, og produktionshastigheden, du har brug for.